From engine blocks to surfboards, statues, helicopters, and mining equipment, 3D Prototyping offers mobile 3D scanning services onsite. Scans can be used to create STL files for 3D printing, full reverse engineering, and inspection reporting. Our qualified technical team is ready to assist at any stage of your project. 3D Prototyping provides a cost-effective solution for engineers, manufacturers, researchers, artists, designers, and toolmakers to scan or verify components. This reduces development and manufacturing lead times while ensuring accuracy.

We utilise the SHINING 3D portable 3D laser scanner, combined with high-end reverse engineering software, to convert and inspect scanned components. As a non-contact system, it easily captures delicate and intricate components, with sizes ranging from 10mm to 2000mm. Laser-ray scanning also allows for accurate scanning of darker objects or shiny surfaces at any time of day.

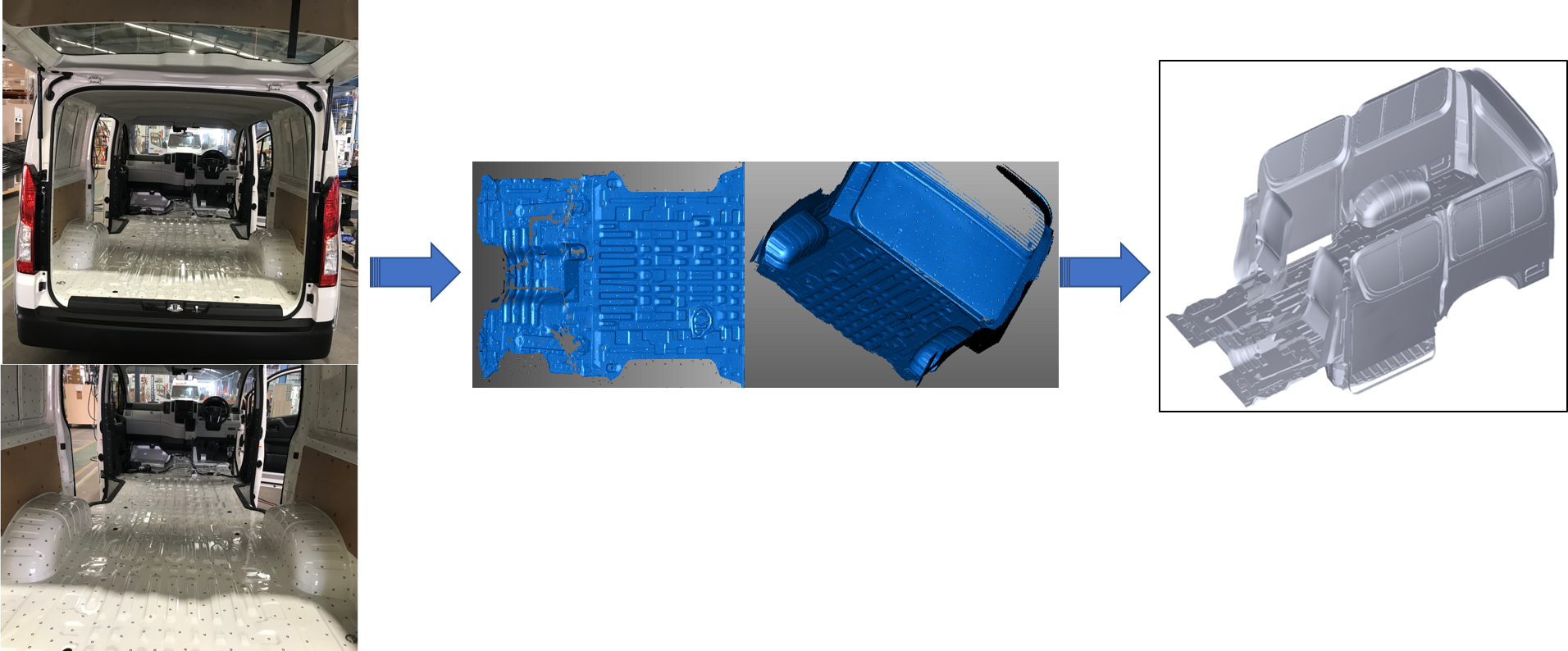

Reverse engineering is a process of capturing data from a physical component, with our Shining 3D optical scanner, from the point cloud data captured we can then export it to the powerful SHININGFORM XOR software where surfaces are added to the polygonized model to produce a water tight surface file, which can then be exported to CAD/CAM and rapid prototyping software.

Suitable files that can be exported in are STL, IGES, TXT, STEP ASCI and parasolid XT.

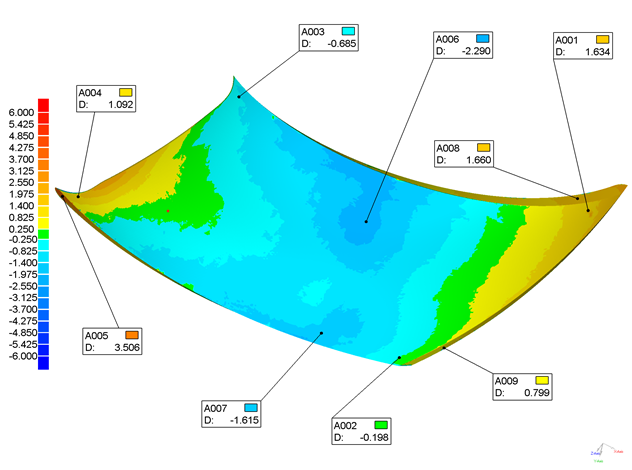

3D Inspection 3D Inspection is a highly accurate, non-contact method for measuring and verifying components against design specifications. Using advanced 3D scanning and inspection technology, we can quickly detect deviations, ensure quality, and maintain consistency in manufacturing.

Key Features of 3D Inspection:

At 3D Prototyping, our SHINING 3D portable 3D laser scanner combined with professional metrology software enables thorough inspection of parts of all sizes, from small prototypes to large industrial components. 3D Inspection helps engineers, manufacturers, and designers ensure accuracy, reduce errors, and maintain high-quality standards throughout the product lifecycle.

Accurately quoting on 3D Scanning, 3D Prototyping require a series of images from different angles; coupled with a measuring device to indicate scale. Complete the form below and fill out the required fields, upload your images and 3D Prototyping will provide a quotation and if needed contact you for further information. Onsite scanning is available on a daily rate for more information please contact us directly on 07 3262 9283.

©2026 All rights reserved